Izvedbena uredba Komisije (EU) št. 182/2011 z dne 18. decembra 2011 o določitvijo pravil o spremembi Uredbe (EU) št. 1303/2013 Evropskega parlamenta in Sveta z dne 11. marca 2011 o določitvi postopkov za izvajanje tehničnih standardov.

Naslov: Shenyang, Liaoning, Kitajska.

Kontaktna oseba: direktor Zhang

Telefon: 400-964-1314.

Mobilni telefon: 86 13904053308

.. . . . . . . . . . .

2025-09-17 30

Www.adsscable.cn

Www.adsscable.cn

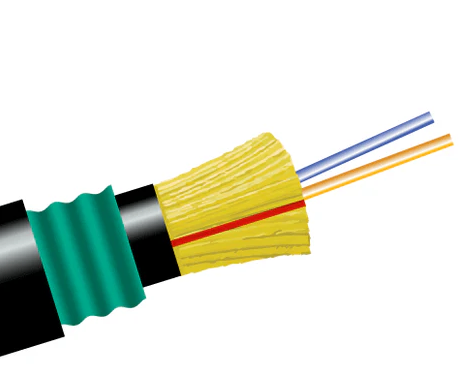

What exactly is a multi purpose break out cable? Essentially, it is a unified assembly containing several individual fibers or copper conductors, bundled together under a durable outer sheath. Each component breaks out into separate legs at designated points, allowing streamlined connections to various endpoints. This architecture supports diverse signals—data, power, or video—within one cable, making it ideal for modern, high-density environments. Its construction often includes strength members and shielding to ensure reliability, outperforming traditional cable bundles in both efficiency and durability.

How does it compare to conventional cabling? Consider this analysis:

| Feature | Multi Purpose Break Out Cable | Traditional Cable Bundle |

|---|---|---|

| Installation Time | Significantly reduced (pre-assembled) | Lengthy (manual handling required) |

| Signal Integrity | Superior (engineered to minimize crosstalk) | Variable (prone to interference) |

| Space Efficiency | Optimized (compact design) | Bulky (occupies Več conduit space) |

| Durability | High (robust jacket and internal structure) | Moderate (dependent on external protection) |

| Cost Over Time | Lower (reduced labor and maintenance) | Higher (frequent repairs and replacements) |

Notably, a 2023 industry report highlighted that prefabricated solutions like break out cables can cut installation time by up to 75%, underscoring their growing adoption in complex projects.

Installing these cables requires attention to detail. Follow these steps for optimal results:

Step 1: Plan the cable route meticulously, accounting for bend radius and distance. Avoid sharp bends or twists that could stress the internal components.

Step 2: Prepare the pathway by clearing conduits or trays of obstructions. Use lubricants for longer pulls to reduce friction.

Step 3: Pull the cable steadily using a designated pulling eye attached to the strength member. Never pull on the break out legs directly, as this could damage the internal structure.

Step 4: Terminate each break out leg according to its function—whether connecting to network switches, power units, or other devices. Ensure proper grounding for metallic elements to prevent interference.

Step 5: Test all connections thoroughly with tools like OTDRs or cable certifiers. Verify signal integrity and label each leg for future maintenance.

⚠ Avoid these common pitfalls:

Exceeding the bend radius during installation, risking fiber damage or performance loss.

Pulling on individual legs instead of the main cable, leading to internal separation.

Neglecting environmental factors (e.g., moisture, chemicals), which can degrade the cable over time.

Selecting the right cable involves assessing the application. For harsh industrial settings, choose cables with oil-resistant or arVečd jackets. In data centers, prioritize shielding to prevent EMI. Outdoor installations require waterproof features like gel filling. The versatility of multi purpose break out cables makes them suitable for evolving needs, such as IoT deployments, where integrated connectivity is essential.

Looking ahead, these cables will play a pivotal role in supporting smart infrastructure. Their ability to consolidate multiple functions into a single assembly aligns with trends toward efficiency and scalability. By reducing material waste and installation complexity, they offer a sustainable alternative for future-proof networks.

Www.adsscable.cn

Checklist for deployment:

Confirm cable specifications (fiber count, conductor types, and jacket rating).

Measure run lengths accurately, including break out points.

Ensure compliance with local codes for grounding and safety.Www.adsscable.cn

Gather all necessary tools for termination and testing.

Schedule post-installation validation to ensure performance standards.

Frequently Asked Questions

Q: Can multi purpose break out cables handle both power and data?

A: Yes, they are designed to integrate diverse conductors, including power and data lines, within a single jacket. Proper shielding prevents interference between different signal types.

Q: Are these cables cost-effective compared to individual cables?

A: Initially, they may have a higher unit cost, but they reduce labor and installation time significantly, leading to lower overall project expenses.

Q: What environments are unsuitable for these cables?

A: Extremely flexible or frequently moved applications might require Več specialized solutions, as break out cables are designed for fixed installations.

Q: How do I customize a break out cable for a specific project?

A: Many manufacturers offer customization options, allowing you to specify conductor types, break out points, and jacket materials to meet unique requirements.

Q: What is the typical lifespan of a quality break out cable?

A: With proper installation and environmental suitability, these cables can last over 20 years, thanks to their robust construction and pre-assembled reliability.